Environment

SRSC LLC following corporate values of mother company CHL-Canada, is highly responsible regarding environment protection considering the usage of hazardous chemicals at hard chrome plating process that is completely controlled.

Environment

SRSC LLC plant was built according to the highest world standards for this kind of industry, that ensures safe and healthy working environment:

- Entire plant floor was covered with chemical resistant epoxy coating,

- Quite large and 6 m deep chrome pit has very tick walls (0,8 m) and is coated with epoxy paint wich is preventing any potential leakage of harmful chemicals directly into the ground.

- Plant is equipped with powerfull ventilation system that ensures fresh air recirculation constantly, in both directions – from the outside to the inside and vice versa.

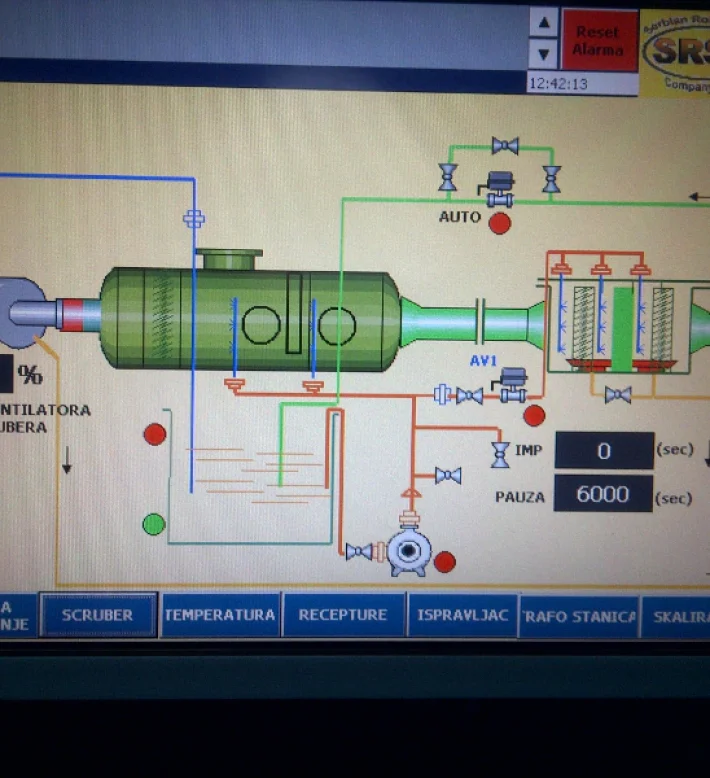

As a side effect of the hard chrome plating process, chrome fumes are safely treated and absorbed by a Scrubber system – special evaporation equipment where chrome particles are being broken by the DI water high pressure through three stages (Droplet separator, Horizontal pulverization Scrubber and Radial Demister).

Scrubber efficiency is proven because at the exit of Radial Demister concentration of harmful chrome six fumes (Cr6+) ensures clean air emission to the values that are far below the EU standards (≤ 0,015 mg/m3).

SRSC applies quite frequently environment conditions monitoring (min. 2 per year), by measuring clean air emission at the Scrubber unit, and by controlling plant interior working conditions in order to protect employees health.

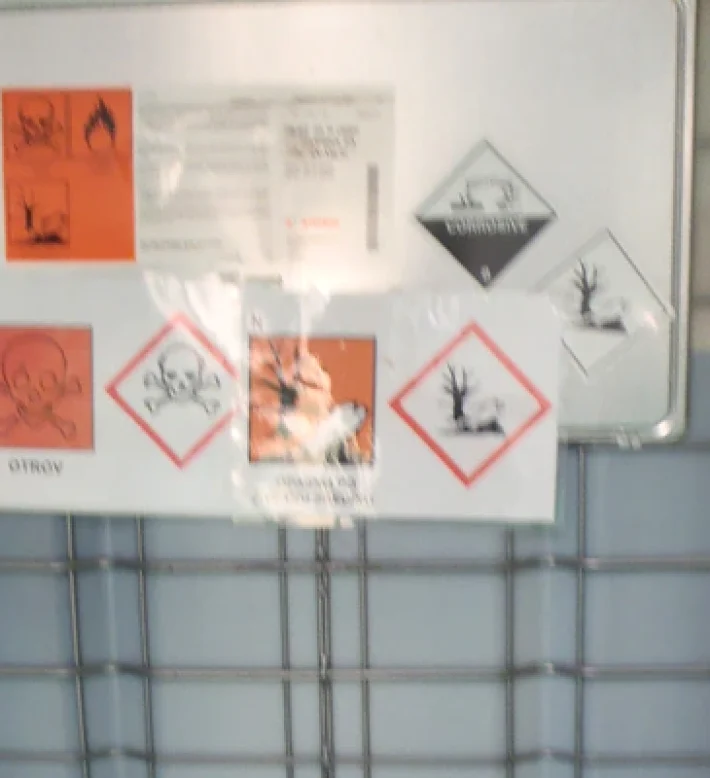

One of SRSC priorities is successful management of industrial waste that is generating during the production process – by grinding and hard chrome plating, where all the waste (solid and liquid) is properly handled, stored, labeled and disposed to authorized recycle centers for further treatment.