Services

Grinding

Grinding represents a process that is done on the grinding machine where the roll surface is brought into an optimal condition by fine stock removal of roll material measured in micrones (value of roughness and stock removal).

Process

Grinding operations prevent later splashing and popping of chrome layer from the roll surface which can result as a chrome peeling. After rolling operation, rolls have to be re-ground to remove metallurgically damaged stock to limit costs where stock removal has to be sufficient to ensure roll surface quality in next rolling.

Equipment

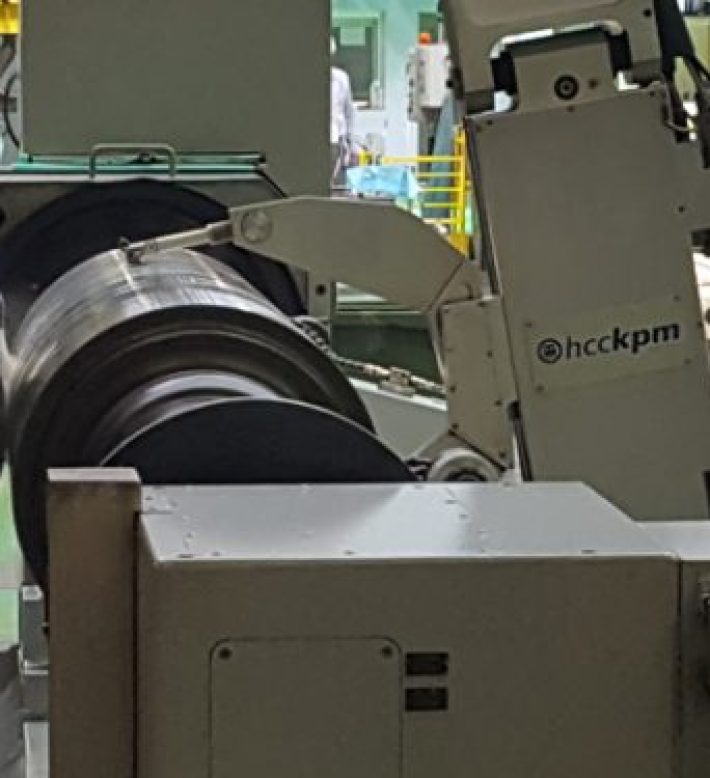

SRSC is equipped with state of the art grinder model WS 450 x 5500 mm CNC MonolithTM made by German machine manufacturer HERKULES Maschinenfabrik Siegen, and this model is dedicated for Rolling Mills work rolls by using brand new sophisticated computer systems:

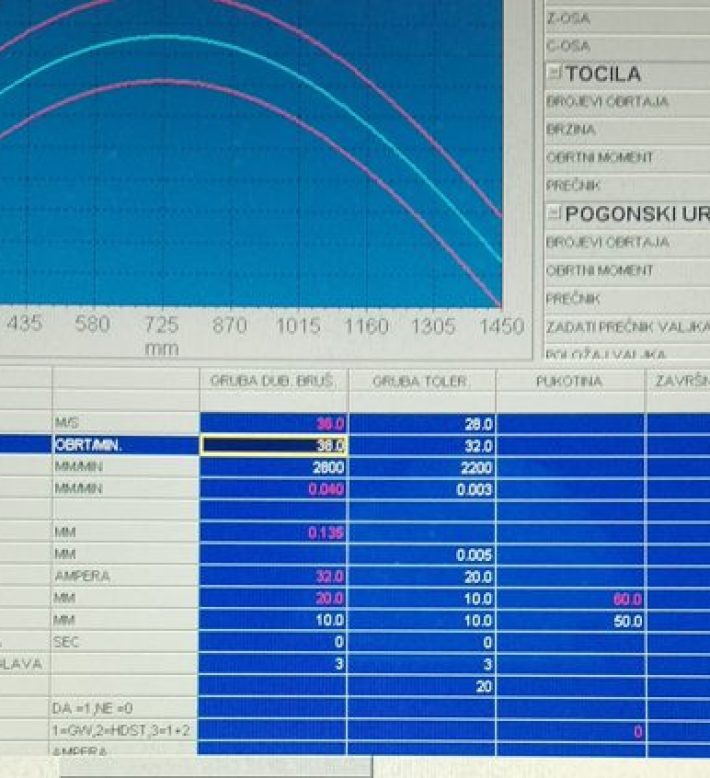

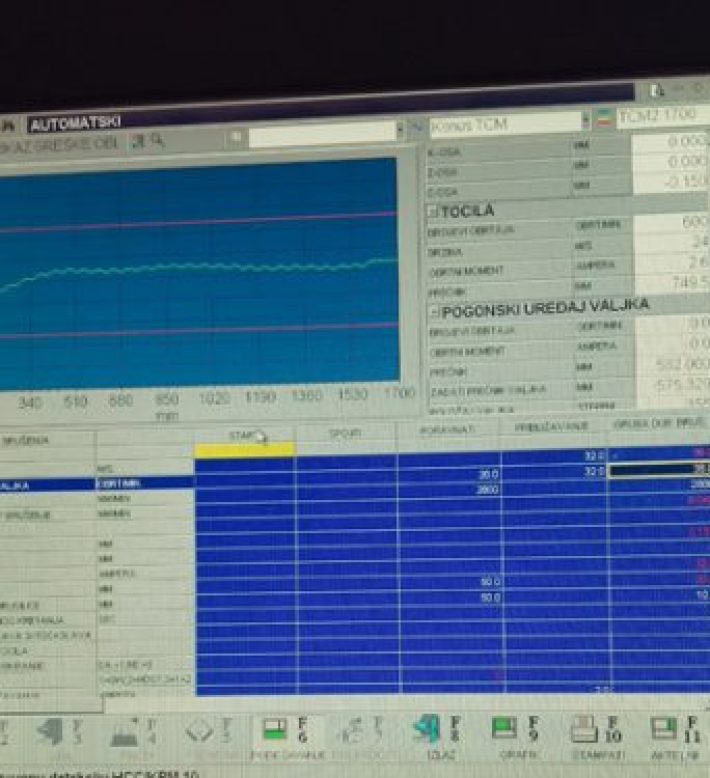

- Integrated fully flexible computer controlled continuous path crowning system (profile measurement system)

- Integrated in-process roll measuring system also for adaptive control for “on the fly” correction grinding (grinding to tolerance, matching of roll diameters, etc.)

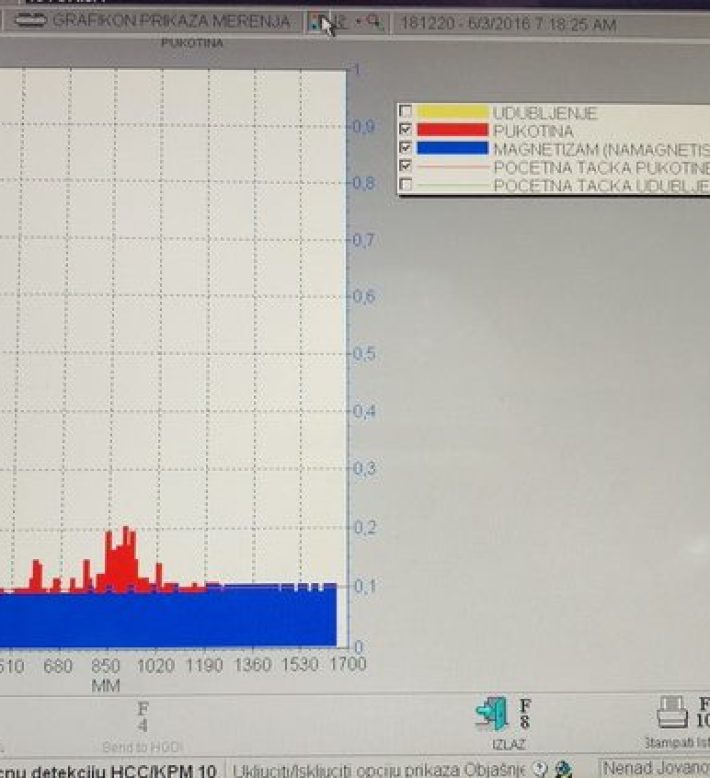

- Eddy current crack detection system

- Ultrasonic roll sub-surface inspection system

- Automatic adjusting system of roll steadies for holding the rolls

- Roll history data storage system (capacity 600 rolls)

- Consistent repeatable roughness (Ra)

Technical Characteristics

Technical characteristics of SRSC Herkules grinder:

Characteristics

Value

Production Capacity

Up to 600 rolls/month (if stock removal not exceeding 0,25 mm per roll)

Roll Dim.

Dmin. = Ø300 mm Dmax. = Ø900-1080 mm, Lmax. = 5500 mm (min. and max. diameter of the roll barrel and overall length)

Roll Neck Dim.

Druk. = Ø130-500 mm (min. and max. diameter of the roll neck that can accept steady rest)

Max. Carrying Capacity

Tmax. = 12 tonne (max. weight of the work roll that can be treated on CNC grinder)

Stock Removal Range

0,1 – 5 mm (0,1-0,25 mm for CRM rolls, and 0,3-5 mm for HSM rolls)

Roughness Range

Ra = 0,5 – 2,2 µm