None Destructive Testing

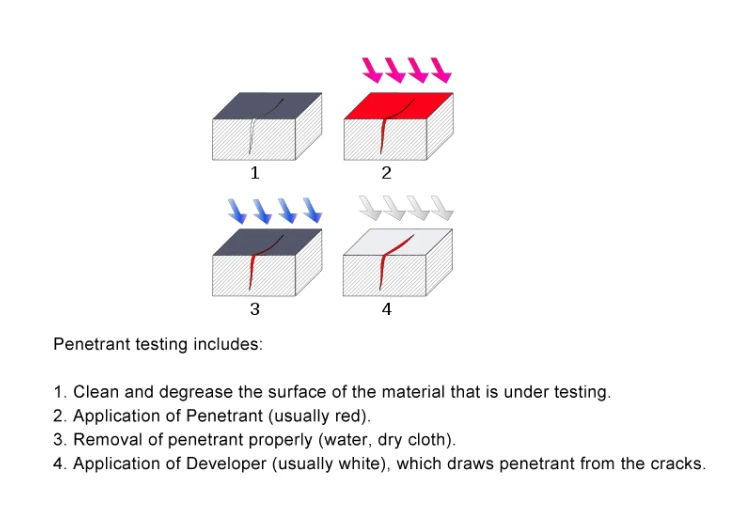

Dye Penetrant Testing

Dye penetrant testing – on previously cleaned and degreased surface penetrant is applied (usually red). After penetrating the eventual crack (during penetration is about 10-15 min.), it removes the penetrant in an appropriate manner (water, dry cloth). At penetrants that need to be removed by water have to be careful and to direct water jet parallel to the metal surface, in order to not displacing penetrant from the cracks.

After drying the metal surface with a dry cloth, it applies a developer who is usually a white color that brings out the penetrant from the cracks, so that on the white metal surface it is easily visible penetrant red line from the cracks. If there is a crack in the tested metal resepctively roll barrel, then the developer will draw penetrant on its side, which will be disclosed as easy to see the red line of penetrant from the cracks in the white (from the developer) the metal surface.

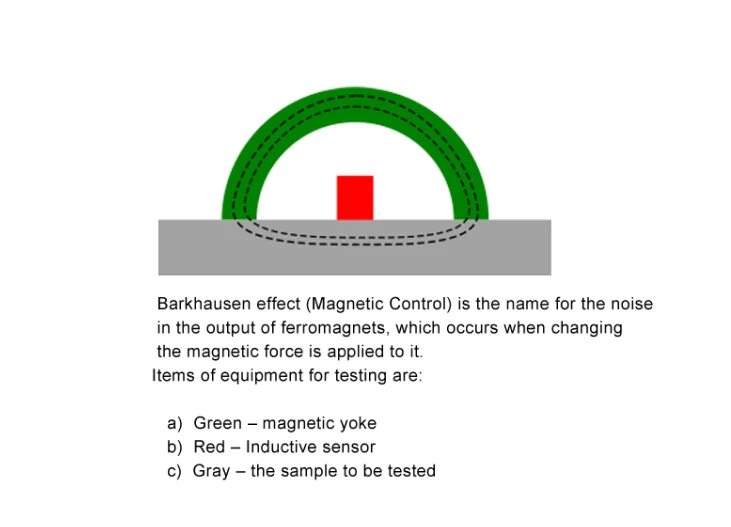

Magnetic Particle Testing

Magnetic particle testing – ferromagnetic material to be exposed to the functioning of the magnetic field, and then to the metal surface apply the iron particles (dry or in liquid suspension). Errors on the surface or right below the metal surface (up to 6 mm deep) produce magnetic poles or distort the magnetic field so that these particles are grouped in places such mistakes and give a visible indication of faults on the surface of the material.