Roll Texturing

Roll texturing service represent a process of changing inside structure of the metal material, or surface structure of the material of the workpiece (work roll from finishing Rolling Mill lines) by controlled electrical discharges where electrical pulses were generated between an electrode and a work roll, which results in the formation of micronic craters and recesses on its surface.

Technology

Generally, nowadays in the world applies four basic techniques of so-called Texturing respectively metal surface texture changes, or precisely steel work rolls:

1. SBT / Shot Blasting Texturing – work roll rotates around its axis and is set in a closed chamber where it is exposed bombing of steel balls (so called buckshot) under the influence of centrifugal rotation wheel, thus causing plastic deformation of the surface structure of the work rolls barrel. Roughness is achieved in the range of Ra=1,5–6,0 micron and can be controlled by the rotational speed of the centrifugal wheel or by the rotational speed of the roll itself, in which however the quality of this method largely depends on the hardness of the roll.

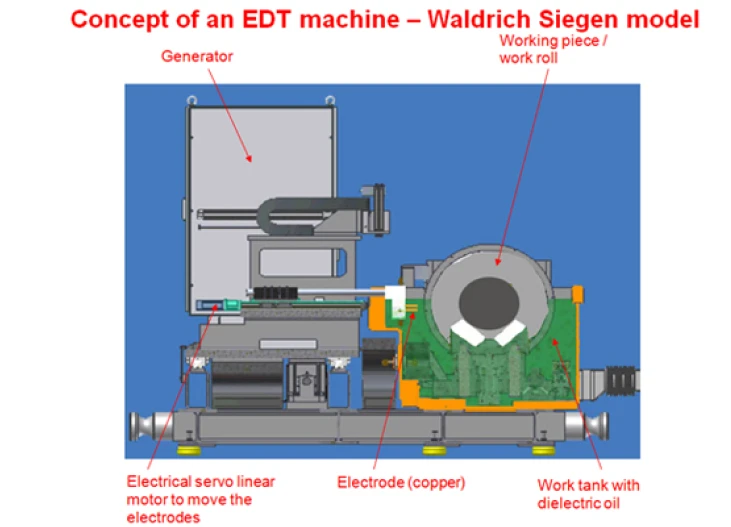

2. EDT / Electro Discharge Texturing – in this method so-called Changes of Textures by Electrical Discharges, work roll rotates around its axis and is set in a tank with a dielectric oil which is on one side or both longitudinal sides of the roll placed a set of electrodes through which the electrical energy with adequate strength are passed and becomes exposed to an influence of the electric pulses in the form of sparks that erode the surface of the roll by forming micron-craters which are characterized by the shape and height of the peaks respectively the peaks and recesses of the crater. Compared with the method of Shot Blasting metal, EDT method enables the achievement a higher number of peaks as well as the frequency of process repetition and a wide range of surface roughness (Ra = 0–15 microns).

3. LT / Laser Texturing – laser beam is directed by the focus on the work roll barrel, whereby a helical rotary wheel by its turning and positioning of the blades interrupts the beam so that the laser operates intermittently and on that way in a controlled environment melts a point of impact on the roll surface by creating the appropriate craters with peaks and recesses. Metal that are melted under the influence of the laser is drained by the plasma and under the influence of inert gas (O2, CO2, Ar). This technology enables the control arrangement of the craters as well as various combinations of peaks size and the shape of the recesses, which obtains controlled different combinations of roughness values.

4. EBT / Electron Beam Texturing – this method uses a very powerful beam of electrons that are in a vacuum environment through the corresponding lens act on a work roll that rotates around its axis and gradually move forward, thus creating micron-craters with a metal rim. The process can be repeated indefinitely with extremely high precision, whereby this method enables creating both type of textures – deterministic and pseudo-stochastic texture.

5. ECD / Electro Chemical Deposition – this method patented by a German-Swiss company TOPOCROM actually is based on a classical electrochemical process of applying hard chrome plating respectively hard chrome plating, with the difference that here the parameters of chrome plating process are controlled by a computer by its combining obtains the required roughness and the corresponding number of peaks. With this method it is possible to achieve a roughness in the range Ra = 0,5 – 12 microns or number of peaks Pc = 100 l/cm.

Methods like SBT, EDT and ECD belong to the group of “stochastic” methods respectively they provides irregular shape of micron craters on the work roll barrel, while methods like LT and EBT belong to the group of “deterministic” methods which obtains regular and proper shape of the subject micron craters.

In fact, of all the above methods only EDT, EBT and LT methods represent a significant improvement now already obsolete SBT method, from the standpoint of roughness stability, the quality of texture undulating, then by high level of forming in deep drawing presses, as well as the color appearance applied to the cold-rolled steel sheet which is mandatory treated by the textured work rolls used in order to manufacture steel strip for car body forming.