GRINDING

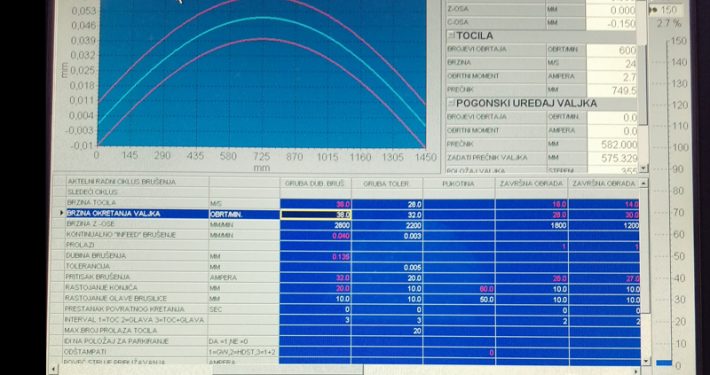

Grinding represents a process that is done on the grinding machine where the roll surface is brought into an optimal condition by fine stock removal of roll material measured in micrones (value of roughness and stock removal).

Grinding operations prevent later splashing and popping of chrome layer from the roll surface which can result as a chrome peeling. After rolling operation, rolls have to be re-ground to remove metallurgically damaged stock to limit costs where stock removal has to be sufficient to ensure roll surface quality in next rolling.

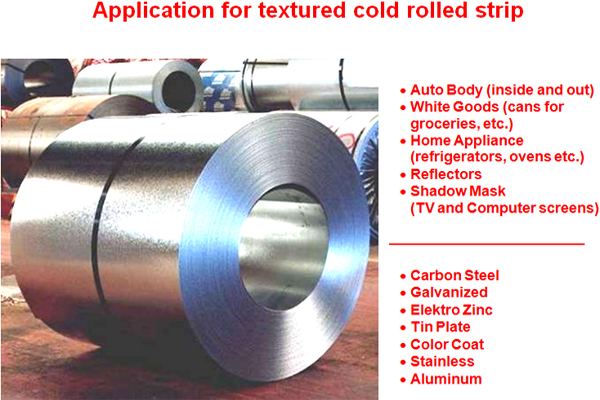

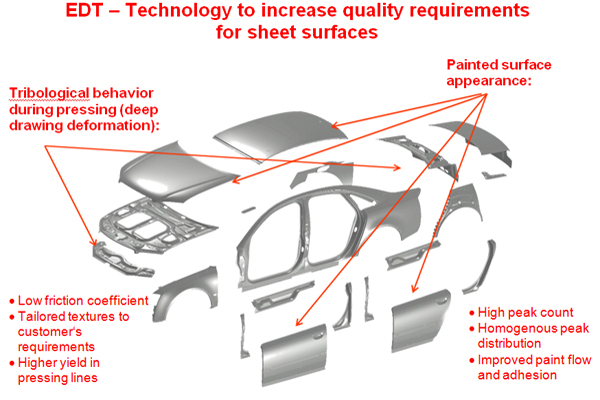

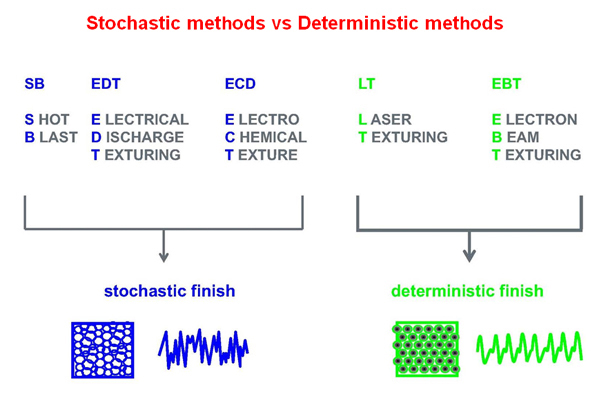

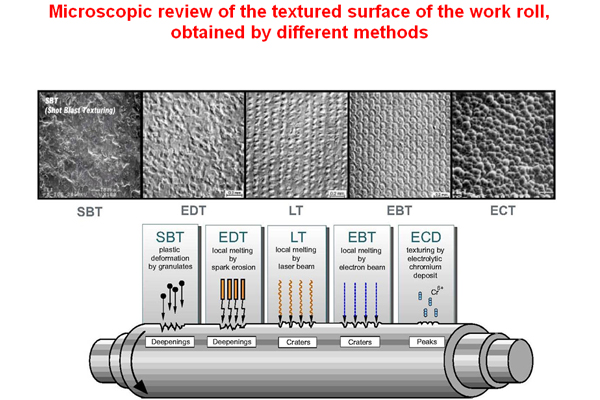

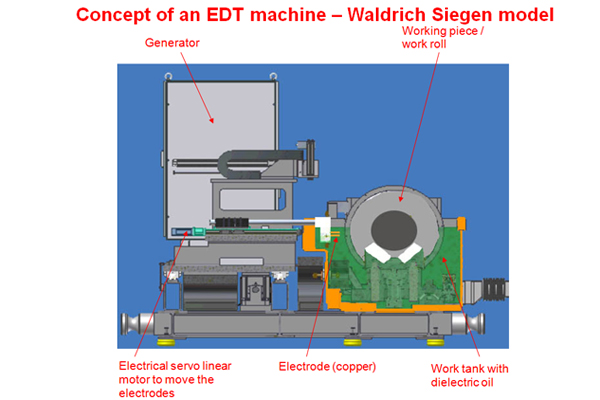

ROLL TEXTURING

HARD CHROME PLATING

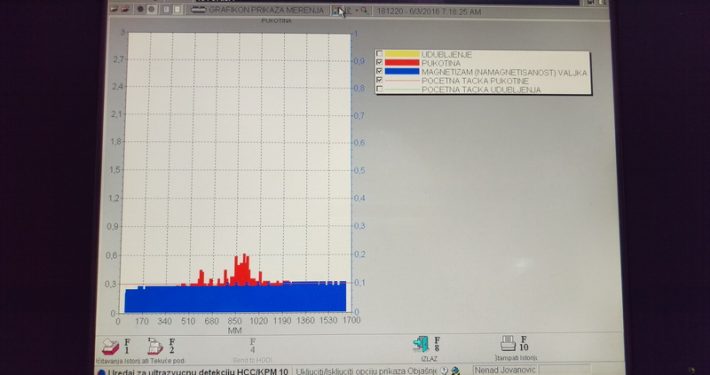

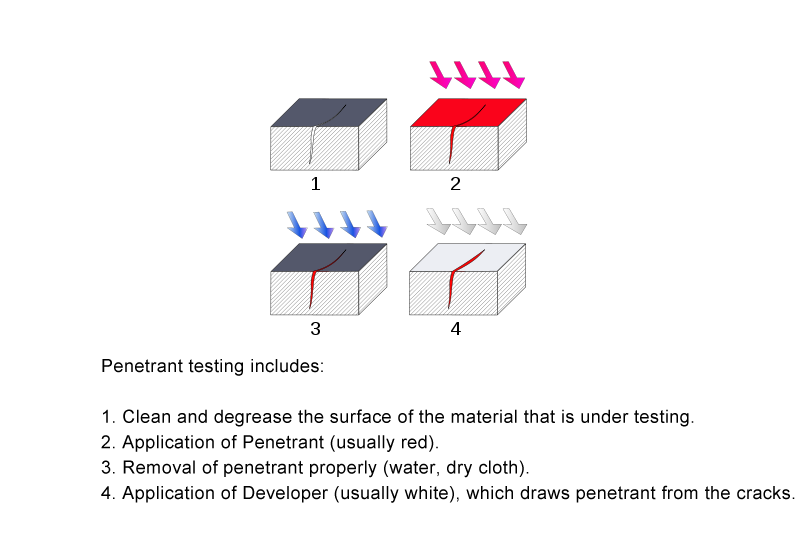

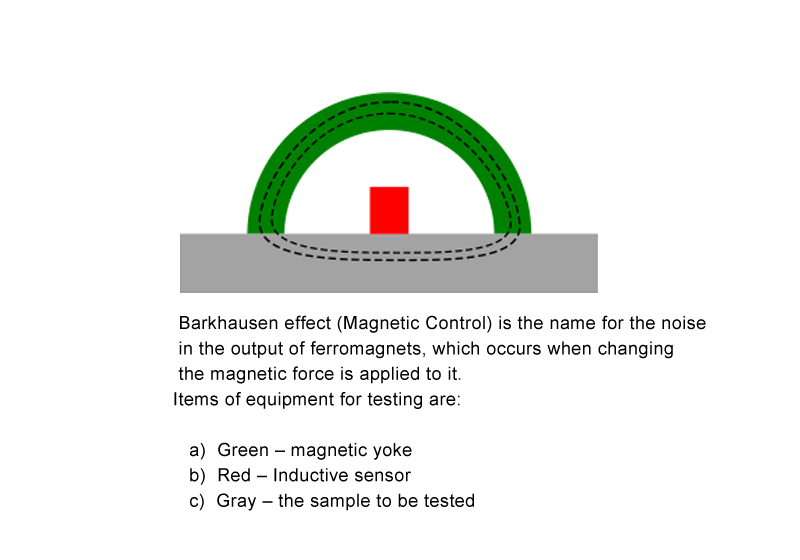

NONE DESTRUCTIVE TESTING

SRSC in daily practice of processing rolls apply special NDT testing, so-called “None Destructive Testing” testing and by the methods of penetrant testing and magnetic particle testing, which are applied by the certified engineers who owns appropriate licenses.