Roll Texturing

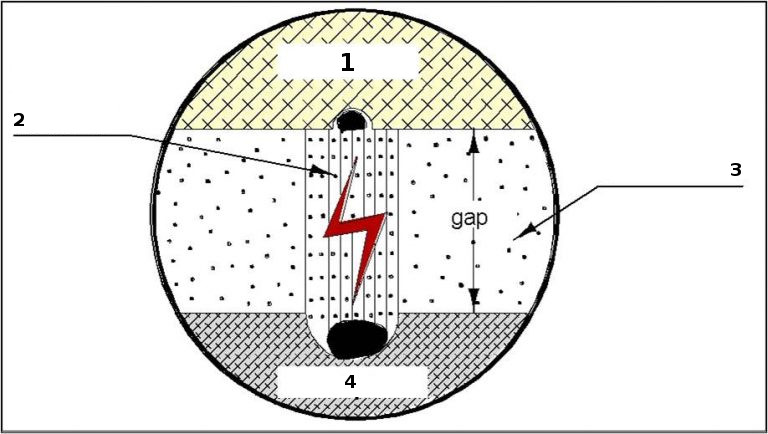

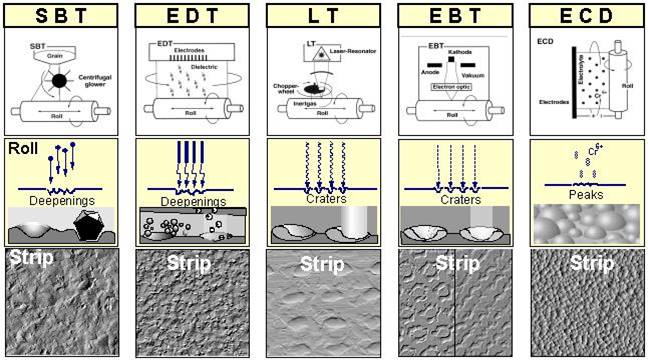

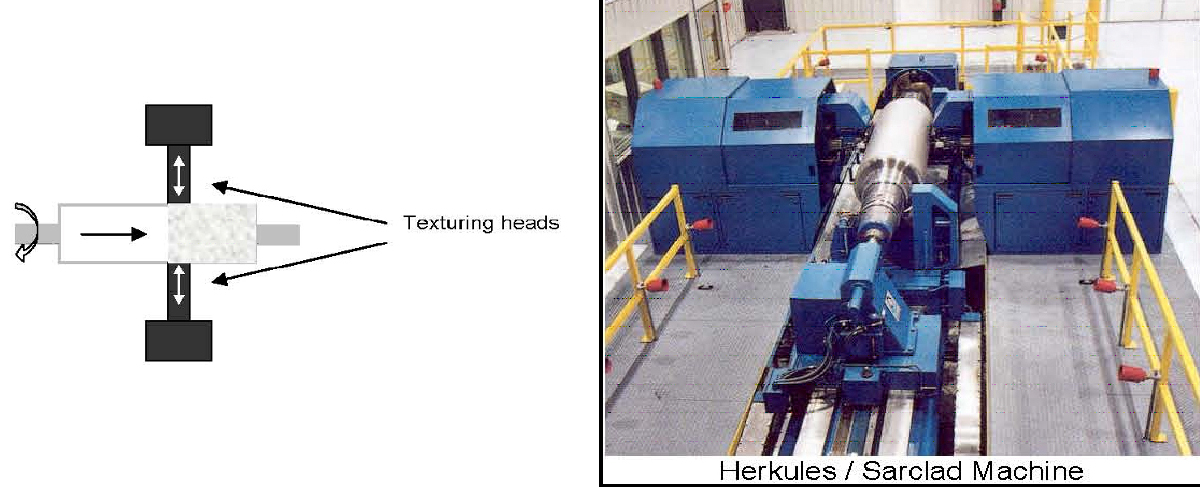

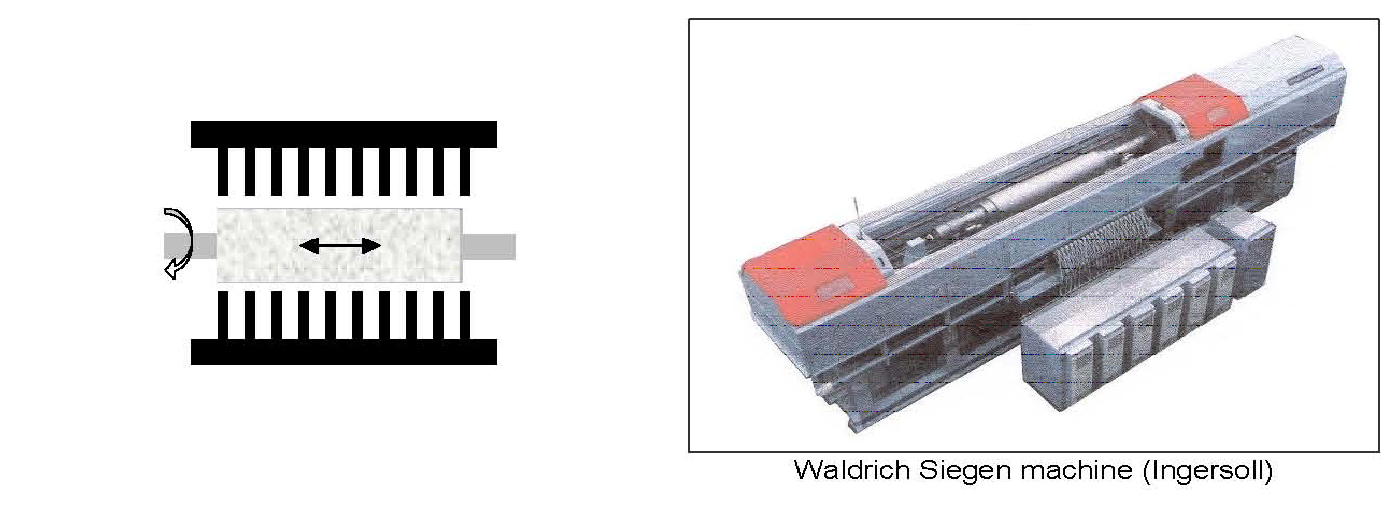

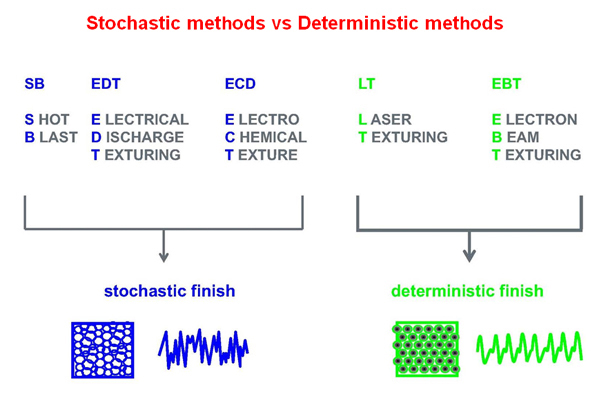

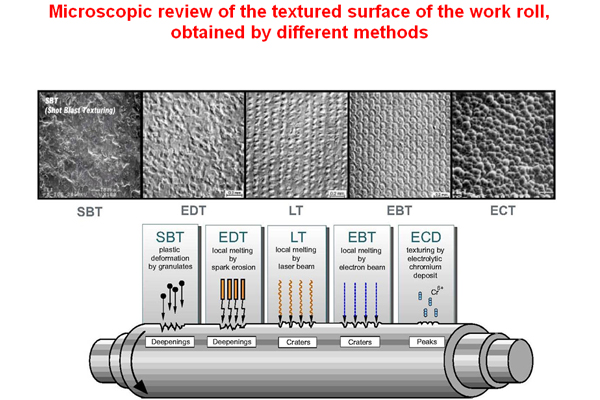

Roll texturing service represent a process of changing inside structure of the metal material, or surface structure of the material of the workpiece (work roll from finishing Rolling Mill lines) by controlled electrical discharges where electrical pulses were generated between an electrode and a work roll, which results in the formation of micronic craters and recesses on its surface.

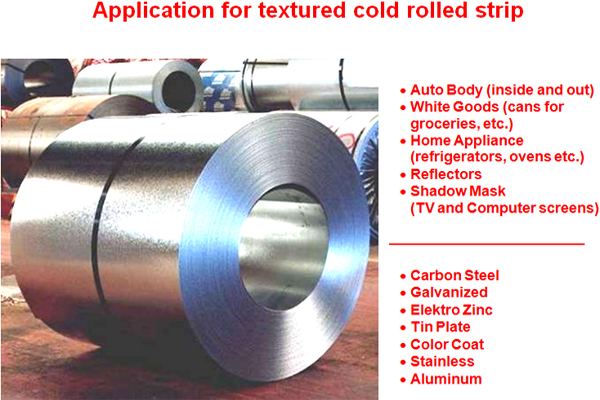

By this process it is created an adequate material structure of the roll resulting in increased quality of the final cold rolled products and specifically: quality uniform over the entire surface of steel (as well as AL) cold rolling sheets, better absorption of color at painting especially car bodies (better painted appearance), possibility of applying a wide range of finishing treatments of the shits, etc. The quality of the roll surface, that can be reached by this process is within the average roughness Ra = 1–10 µm and 240 to 25 Pc / cm (Picks per cm area).

This treatment allows a higher number of micron-formed craters/peaks on the roll surface, then a higher repeatability of the process and a wider range of roughness achieved.

Cold rolled steel sheets for the automotive industry and other related steel products obtained by pressing (plastic deformation of the sheet), are basically all manufactured by the work rolls with the changed texture of the material surface.

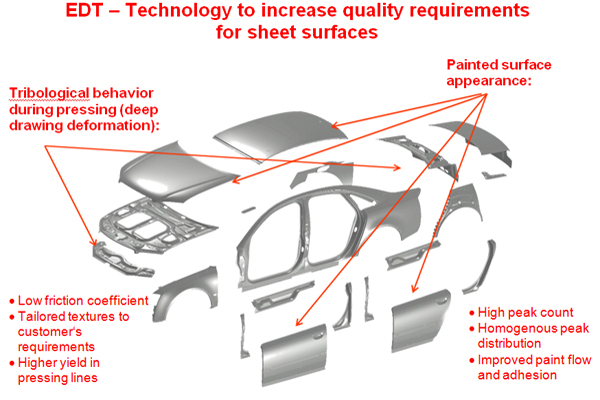

There are two main reasons for texturing the work rolls:

- Increasing the level of forming (deformability) cold-rolled steel sheets, due to the fact there are in the micro craters and recesses on the surface of a metal sheet that are transferred from the work rolls during the rolling process, rolling oil retains and allows constant lubrication of contact surfaces of the drawing press and sheet steel during the process of several stages of the forming respectively deep drawing (pressing).

- mproving the adhesion of paint and finishing process of the painting cold rolled steel sheets with such texture, which is one of the main demands of the automotive industry.

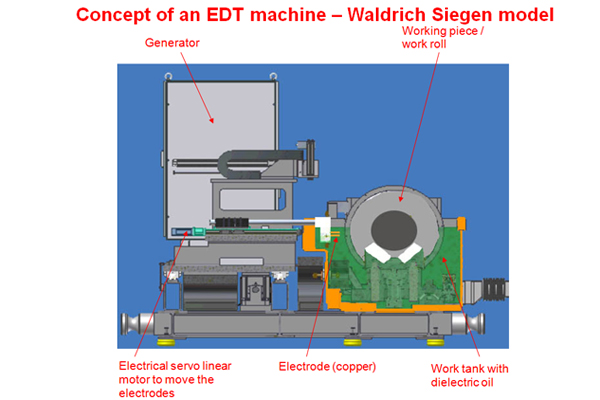

Texturing process is based on the erosion of metal surfaces of work rolls in their processing, under the influence of an electric arc / spark which is formed between the electrode (respectively Anode, which is usually dipped in a dielectric oil) and the workpiece / roll which are textured (in this case the work roll is Cathode).

2. 2. Electric power pulse / Ionized (conductive) channel of forming the sparks

3. 3. Non-conductive (dielectric) Oil

4. 4. Work piece / work roll from Cold Rolling Mill stand

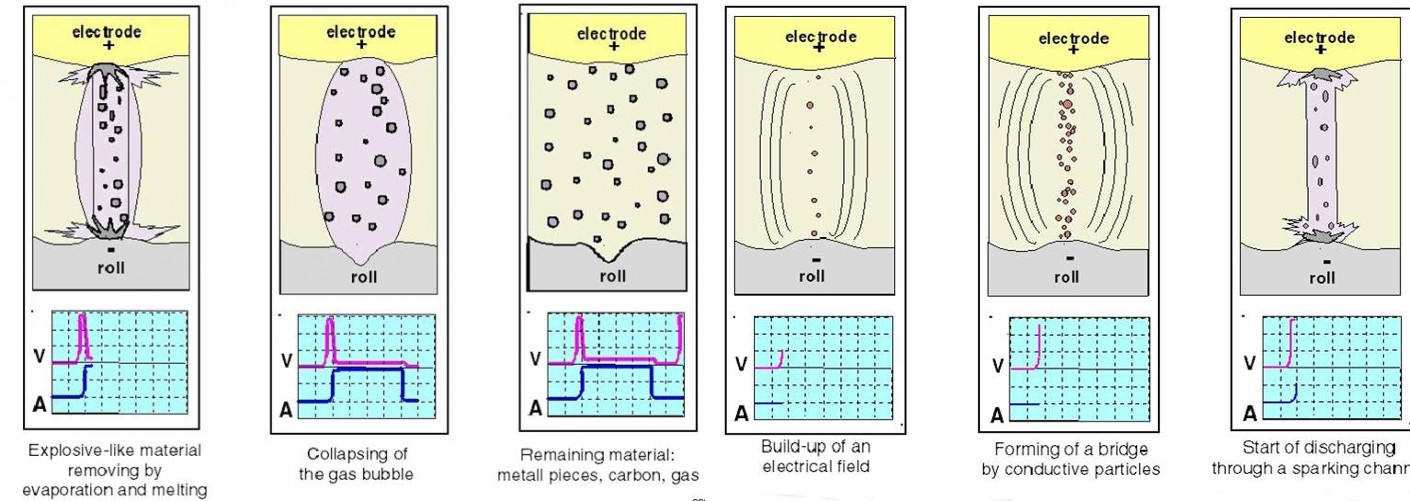

As the texturing machine during operation creates a micronic craters by the mean of controlled electrical discharges, then in such working environment with dielectric it comes to forming of an electric discharge between the electrode and the work roll, wherein the electrical pulse in the form of the sparks drains away eroded particles from the surface of the work roll.